“ENGINEER YOUR SMART FACTORY BLUEPRINT”

3-Day Workshop, 7-Day Overseas Trip, 12-Month Mentorship

Top Learning Outcomes:

• Identify company’s maturity level, readiness, and focus areas

• Employ design thinking business canvas in industrial transformation

• Evaluate and incorporate model or trial-solutions

• Experience & understand Industry 4.0 best-practices at companies in Germany

• Exchange knowledge and feedback through networking and discussion opportunities

• Incorporate transformation strategies into Smart Factory Blueprint

• Gain insight from sessions conducted by domain experts & knowledge partners

• Application of transformation initiatives through a 12-month mentorship programme

PROGRAMME OVERVIEW

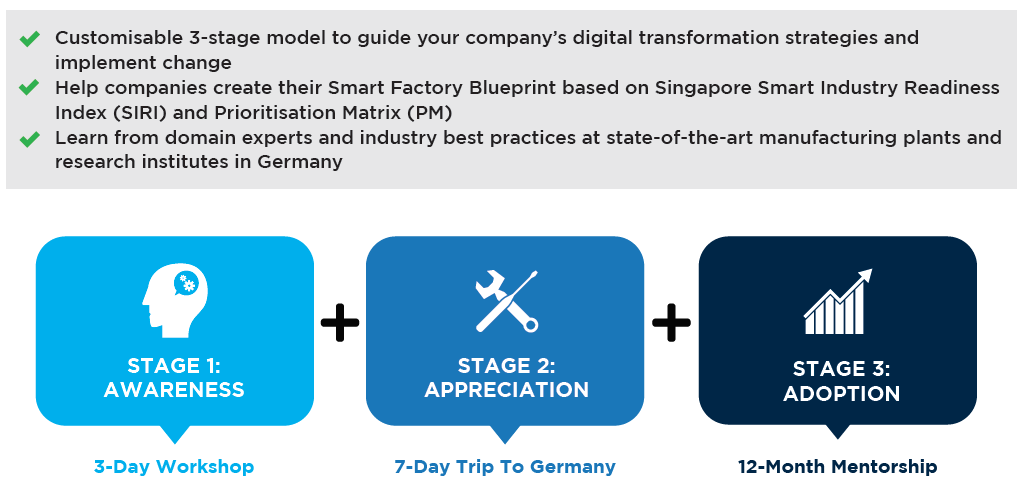

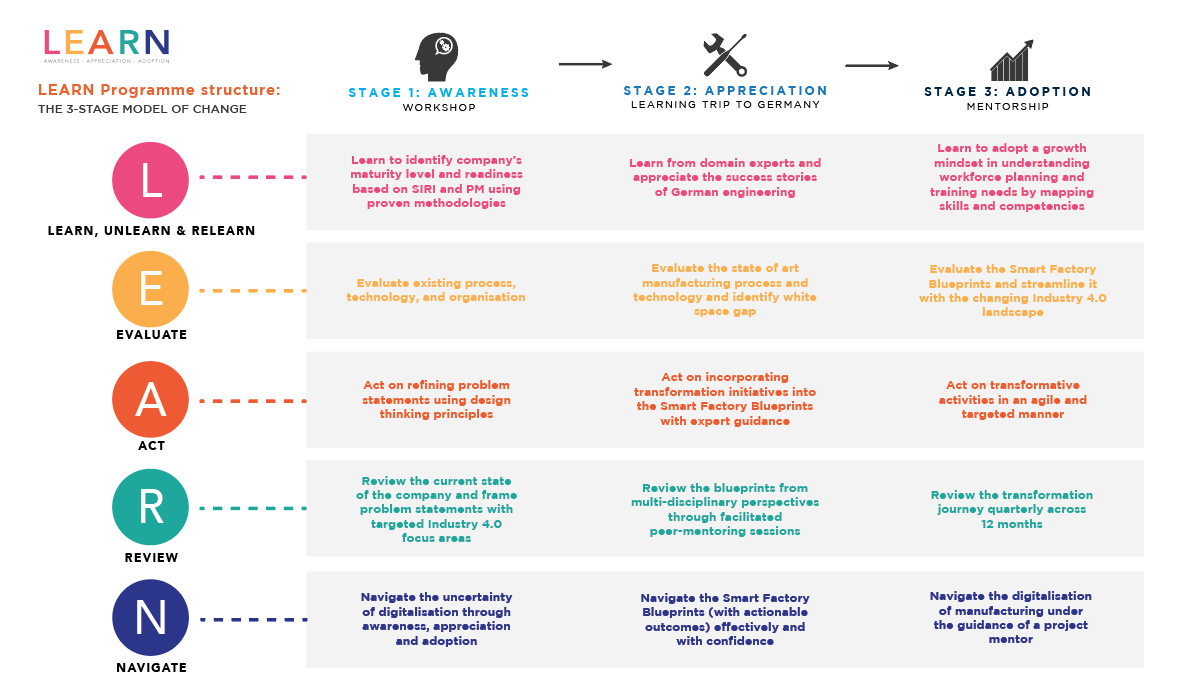

Developed by Technical University of Munich (TUM) Asia and in partnership with TÜV SÜD Asia Pacific – COE Digital Service, the LEARN Programme adopts a 3-stage model of change to help companies engineer and implement their smart factory transformation blueprint based on the Singapore Smart Industry Readiness Index (SIRI) and the Prioritisation Matrix (PM). It aims to help companies progress from a state of awareness, to appreciation and eventual adoption of a holistic transformation strategy that addresses the core elements of Industry 4.0 (Process, Technology and Organisation).

PROGRAMME BENEFITS

Tailored Approach For Organisational Needs

Companies will benefit from the facilitated knowledge exchange where valuable insights and strategies are shared, refined and redesigned to suit their organisations’ needs.

Peer Mentoring By Industry Experts

The academic-industry peer mentoring eco-system consists of domain experts, knowledge partners and project team members from different industries offering multi-disciplinary perspectives.

Follow-up Project Mentorship

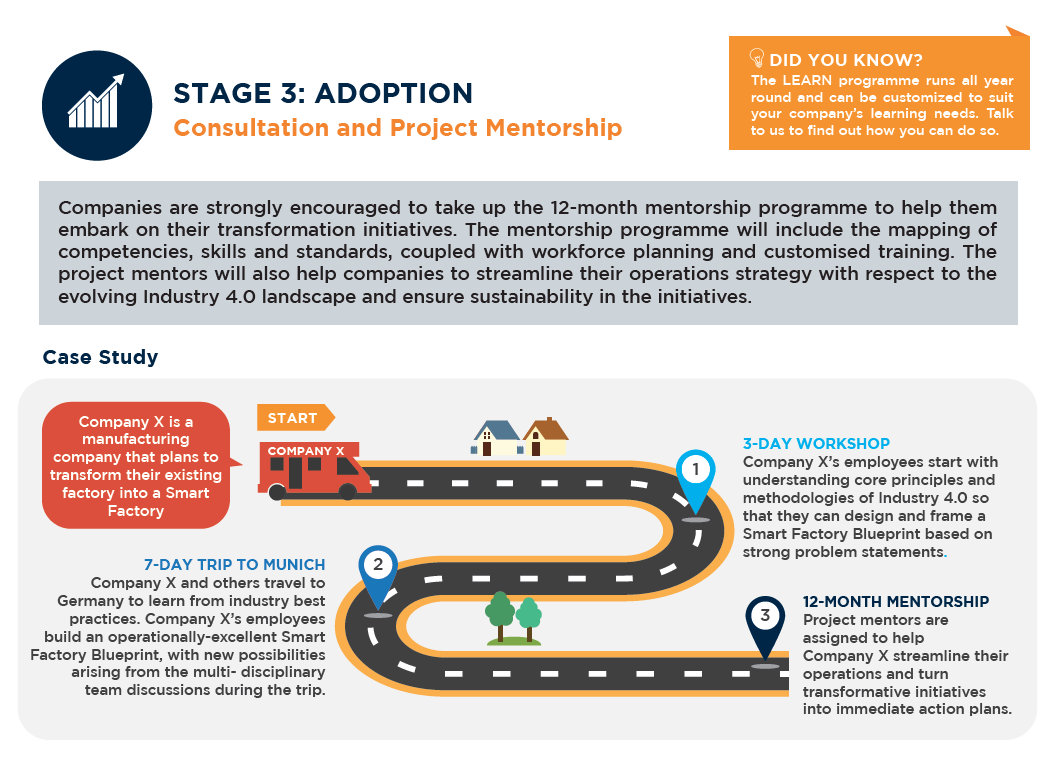

This programme includes a follow-up consultancy and 12-month project mentorship to help companies implement their smart factory blueprint.

PROGRAMME FEES & FUNDING SUPPORT

STAGE 1: AWARENESS (3-Day Workshop)

26 – 28 February 2020

13 – 15 April 2020

SGD $2,000 per pax* (before 7% GST)

Up to 90% SkillsFuture Funding available

Pre-assessment: 6 Hours

3 days: 24 Hours

Total: 30 Hours

STAGE 2: APPRECIATION

March – April 2020

SGD $8,200/pax (before 7% GST)

Fees are subjected to changes

STAGE 3: ADOPTION

Follow-up Mentorship Project

Project-based fees

Companies can apply for Enterprise Singapore funding. T&Cs apply.

*Published in October 2019

WHO SHOULD ATTEND

- Targeted at, but not limited to manufacturing (i.e. automation, electrical/ electronic and mechatronics, food, medical technology), fast-moving consumer goods (FMCG), machinery and systems, precision engineering and logistics sectors

- Recommended team size and composition (up to 4 per company):

– 1 x Senior Management

– 1 x Operations

– 1 x Supply Chain

– 1 x Engineering

– 1 x Human Resource

COURSE ENROLMENT

- Interested companies must be a locally registered or incorporated entity in Singapore

- Suitable for both small and medium-sized enterprise or large local enterprise

- Companies must submit details of their organisation, main customer base and overview of current business activities

- Successfully enrolled individuals and companies must complete and provide all the necessary enrolment documents, accepting all terms and conditions of the programme.

WORKSHOP

View our Workshop Flyer by clicking here.

PROGRAMME BROCHURE

View our brochure by clicking here.

- Register Your Interest

- Stage 1: Awareness

- Stage 2: Appreciation

- Stage 3: Adoption

- LEARN Programme Leaders

For more information, please contact:

TUM Asia, Office of Executive Development

Email: exd@tum-asia.edu.sg

Tel: +65 6777 7407

[gravityform id=”21″ title=”true” description=”false”]

Workshop Objectives

- Understand and apply SIRI and the PM

- Understand core principles, frameworks and methodologies of Industry 4.0

- Determine the aspirational state of the company guided by its business objectives

- Generate actionable problem statements in Industry 4.0 focus areas

- Introduction to TÜV SÜD solution taxonomy and Fraunhofer digital media technology

Learning Outcomes

-

Identify company’s maturity level, readiness, and focus areas using data-driven approach

- Reference Architecture Model for Industry 4.0 (RAMI) and respective standards

- Design thinking business canvas – specific application to industrial transformation

- Frame problem statements into the Smart Factory Blueprint

- Identify the right technology use cases based on business priorities, size of impact, and organizational readiness

- Evaluate and incorporate model / trial-solutions as identified by TÜV SÜD and Fraunhofer Singapore

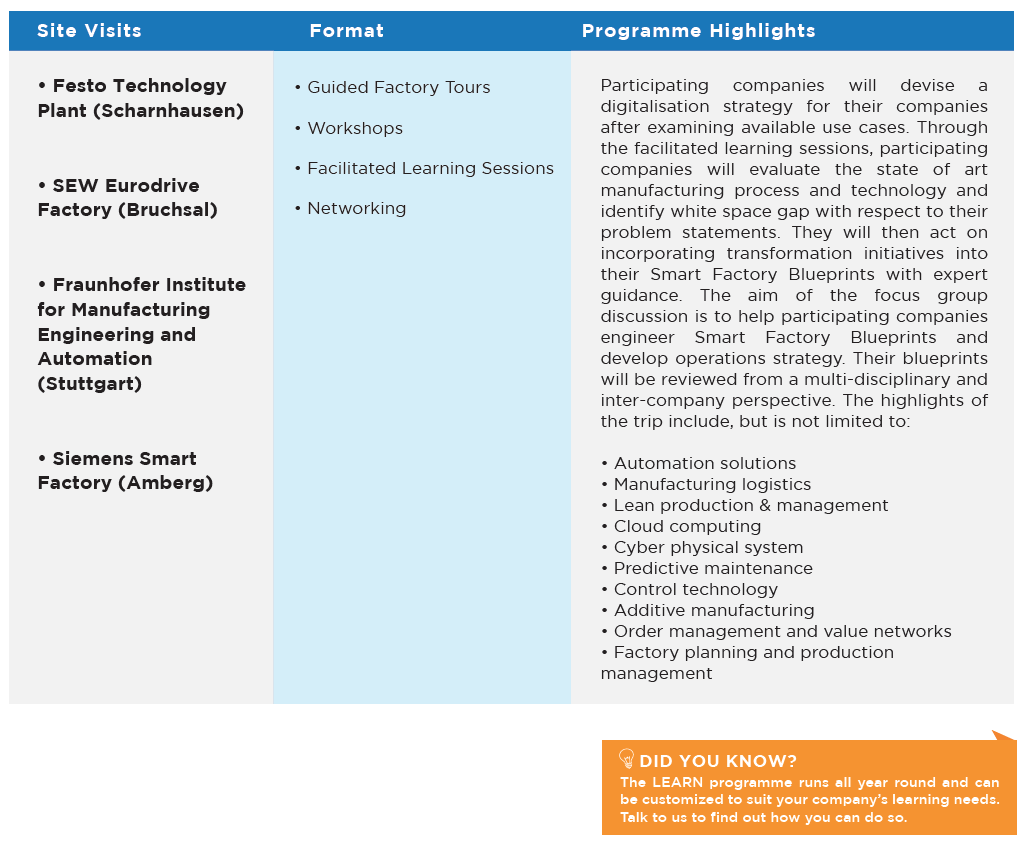

LEARNing Trip Objectives

- Experience Industry 4.0 best-practices at every guided factory tour

- Learn from industrial practice and domain expertise to implement Industry 4.0 technologies

- Understand the digitalisation strategy of each company from shop floor to management level

- Exchange knowledge and feedback through networking and discussion opportunities

- Incorporate appropriate transformation strategies into Smart Factory Blueprint through facilitated learning sessions conducted by domain experts and knowledge partners

LEARNing Trip To Germany – Programme Highlights

| Speakers | About Them |

Frank ReppelManaging Partner and Founder of Reppel & Partners Pte Ltd

Prof. Dr.-Ing. Dipl.-Kfm. André Krischke Logistics and Supply Chain Management |

Frank Reppel obtained his M.Sc. in Physics from the Karlsruhe Institute of Technology (KIT). He is currently the Chairman of the Innovation and Digitalisation Committee of the Singaporean German Chamber of Industry and Commerce (SGC) and the President of the Singaporean Alumni Club of KIT. Frank is the managing partner of Reppel & Partners Pte Ltd, a management consulting company focused on Industrial Transformation and Digitalisation. He has worked in various leading roles in the ICT industry in Europe and Asia over the past 25 years after having started in a shop floor control systems company in the late 80s. Before the founding of Reppel & Partners, Frank has worked for large MNCs such as Siemens, and was also Chief Operating Officer for an Asian operation of a European MNC. Living in Singapore since 1997, Frank is leading digitalisation efforts, including business intelligence and Industry 4.0 projects, and has helped TÜV SÜD’s Center of Excellence here in Singapore incubate its Industry 4.0 consulting practice. In that role, Frank was one of the very first accredited SSIRI workshop assessors and is a Singapore Certified Management Consultant.

Professor Andre Krischke did his Doctorate in Mechanical Engineering at the Technical University Munich (TUM) and moved on to study Business Administration at the University of Hagen, with majoring in Operations Research and Strategic Planning. He was a business consultant and project manager at McKinsey & Company, Inc. and became a global supply chain manager at OSRAM GmbH Munich. He is a professor for supply chain management at the University of Applied Science Munich (MUAS). His research focus is on quantitative approaches and simulation in supply chain management, manufacturing planning and control, sales and operations planning as well as business strategy dynamics / complexity management and strategic foresight. He also participated in industry projects involving the application of advanced manufacturing processes and systems and smart supply chains. Professor Krischke is also teaching in the Specialist Diploma in Advanced Digital Manufacturing offered by TUM Asia. |