News

Upcoming Events

mobil.TUM 2025 – 14th International Scientific Conference on Mobility and Transport

- In-person | Singapore

Admission Webinar Series for August 2025 Intake

- Online

Info Session Series 2025

- Online

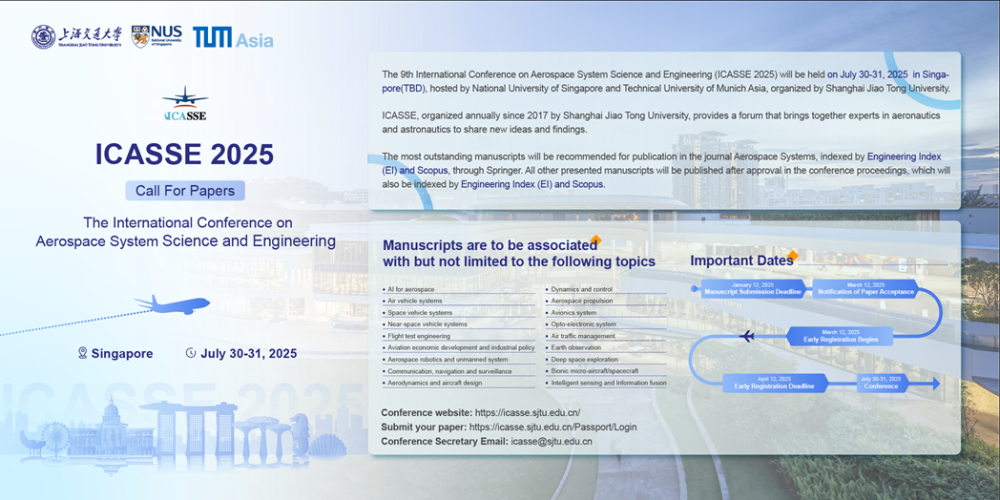

The International Conference on Aerospace System Science and Engineering (ICASSE) 2025

- In-person | Singapore

Find the Right Programme For You

Prospective Students

Prospective Students

Advance your expertise, expand your opportunities, and connect with leaders in your field through our graduate programmes.

Prospective PhD Students

Executives and Professionals

Why TUM

#1

#13 in Global Employability Survey

Discover New Possibilities

Students

Alumni

Yuanyuan Yin

Class of 2021, MSc in Integrated Circuit Design

I aspired to a career in IC Design and sought a graduate programme to equip me in this field. TUM Asia’s programme met my needs, with courses taught by esteemed professors from NTU and TUM.

Brandon d'Cruz

Class of 2024, MSc in Green Electronics

The MSc in Green Electronics at TUM Asia is rooted in the rich cultures of Singapore and Germany. The professors provided valuable insights into cultural nuances, helping me appreciate and communicate effectively in global work environments.

Zhang Shengguo

Class of 2024, MSc in Rail, Transport and Logistics

During my internship as a research engineer, I collaborated with my TUM Asia senior, a software engineer at ST Engineering, to deliver real-time transportation management solutions. It was rewarding to see the impact of our work firsthand.

Aswin Haridas

Class of 2012, MSc in Aerospace Engineering

The highlight of my TUM Asia experience was the cultural diversity and learning opportunities during my internship and thesis in Munich. Conversations with diverse people made me more inquisitive in the things I see and experience.

Dr. Ronny Sondjaja

Class of 2004, MSc in Industrial Chemistry

My studies gave me international exposure, fostering an appreciation for diverse cultures and the ability to leverage this diversity for co-innovation and team growth. I learned from professors in both Germany and Singapore, each with a unique teaching style.

Connect with Us

Stay Informed, Stay Empowered.

Join our mailing list to be the first to hear about our programmes, events, and news — delivered straight to your inbox.

- Explore our in-demand programmes

- Stay updated on upcoming events

- Receive insightful news and stories

Academic Building North, ABN-B2a-08,

Nanyang Technological University (NTU)

61 Nanyang Drive

Singapore 637335

Phone: +65 6777 7407

© 2025 Technische Universität München Asia

German Institute of Science & Technology – TUM Asia Pte Ltd

PEI Reg. No. 200105229R | Registration Period 13.06.2023 to 12.06.2029

TUM Asia's Exciting Move to New Campuses at NTU & SIT - Learn More!